Dye Carrier

Water is not used to carry the dye into the fabric. A different material is employed which is completely recovered after dyeing and reused for the next batch

Water is not used to carry the dye into the fabric. A different material is employed which is completely recovered after dyeing and reused for the next batch

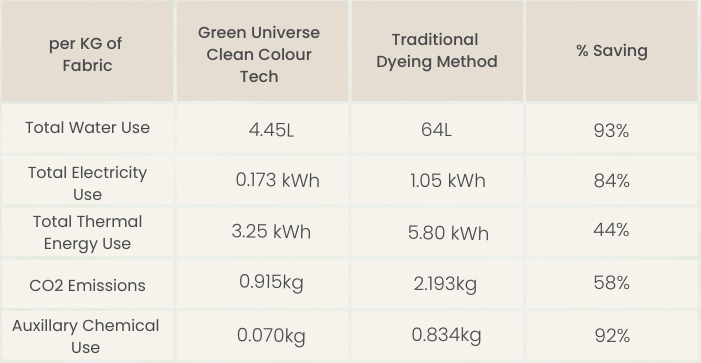

Clean Colour technology works at a temperature 20°C lower than the traditional method, reducing evaporation and energy consumption.

In this process, the fabric retains 95% of the dye, compared to 75% in traditional methods. No salt is needed to fix the dye, leading to shorter rinsing times.

Process time decreases by 50%, reducing energy consumption and CO2 emissions.

Compared to common methods, less dyeis needed to produce excellent colour fastness. Clean Colour operates at lower temperatures, saving energy and reducing emissions. The minimal waste water is clean enough to be recovered and reused for any purpose and 100% of the waterless dye carrier can be recovered during rinsing and reused. Even more, only 15% of textile waste is produced per 1000kg of dyed fabric.

Compared to common methods, less dyeis needed to produce excellent colour fastness. Clean Colour operates at lower temperatures, saving energy and reducing emissions. The minimal waste water is clean enough to be recovered and reused for any purpose and 100% of the waterless dye carrier can be recovered during rinsing and reused. Even more, only 15% of textile waste is produced per 1000kg of dyed fabric.